A Broaster Guide to Pressure Fryers

The role of a pressure fryer in the cooking process depends on the food being prepared, but in most cases, the goal of pressure frying is to ensure that moisture and flavor is sealed in while excess cooking oil is sealed out. It’s an effective method for preparing freshly breaded, and bone-in dishes where it’s essential to keep in the natural juices that enhance flavor.

Though pressure frying was invented sometime towards the end of the 1930s, there have been many advancements in pressure fryer design over the years. Innovative manufacturers like Broaster are leading the way in adding a range of high-tech capabilities that are making pressure frying easier and more energy efficient. Many of their models adjust the cooking time automatically to accommodate for varying sizes and temperatures of loads. Some even double as data-trackers, allowing operators to monitor everything from food production to oil management.

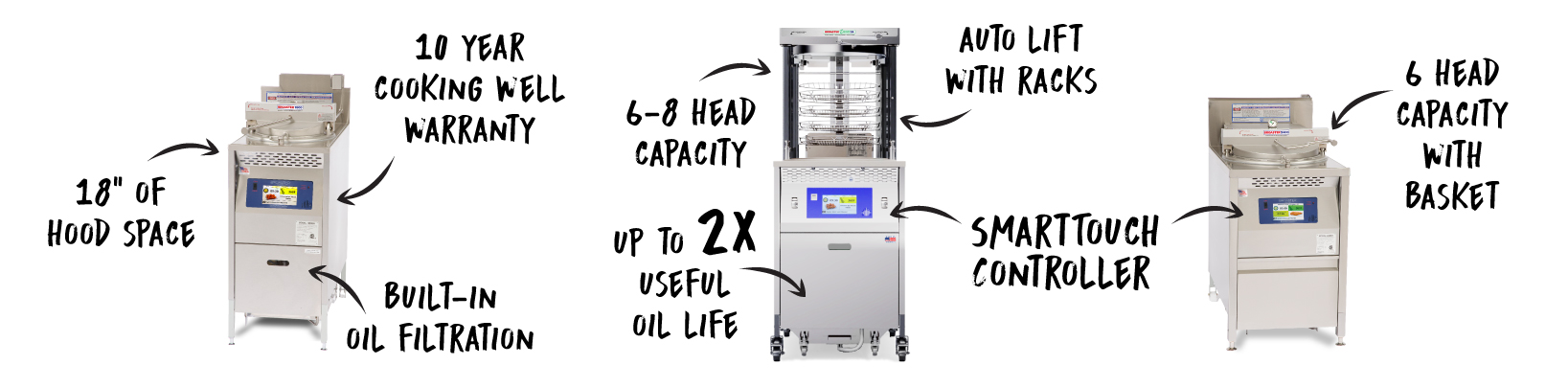

Broaster pressure fryers come in a variety of sizes and finding the right fit for your operation is determined by examining your product mix and projecting how many items are needed per hour. Factor in whether you cook and hold large batches or cook to order. Consider the floorspace under your hood and compare the throughput per square foot of different models.

When choosing between gas and electric models, gas tends to be less expensive than electric when factoring in the long-term operating costs, though both options are always available to fit your location’s needs.

The Broaster E-Series pressure fryers allow operators to easily manage back-of-house labor while providing their customers with notable moist and flavorful foods. They’re specifically designed for high volume production and can cook up to 32 pieces of fresh bone-in chicken per load in as little as 11-12 minutes. It’s also extremely efficient, offering savings of up to 25% on energy costs.

The Broaster E-Series pressure fryers allow operators to easily manage back-of-house labor while providing their customers with notable moist and flavorful foods. They’re specifically designed for high volume production and can cook up to 32 pieces of fresh bone-in chicken per load in as little as 11-12 minutes. It’s also extremely efficient, offering savings of up to 25% on energy costs.

The Broaster 1600 is the smallest footprint, most cost-effective medium-capacity pressure fryer available on the market today. Compact, reliable and easy to use, the 1600 uses only 3.2 square feet of floorspace under the hood. The 1600 also offers the capability to pre-program up to 10 different cook cycles for quick and easy preparation of various menu items.

The Broaster 1800 offers Broaster’s best combination of capacity and space efficiency. With the ability to cook up to 40 pieces of fresh bone-in chicken per load in as little as 10 minutes, the fast and productive 1800 is specifically designed for high volume output. Its large capacity provides more room for product, minimizes sticking, and produces delicious, superior quality food.

The Broaster 2400 is a large-capacity, high efficiency pressure fryer designed to cook large quantities of product. The 2400 can produce up to 48-64 pieces of fresh bone-in chicken per cook cycle. It’s also extremely easy to operate as its patented SmartTouch™ feature offers the capability to pre-program up to 10 different cook cycles for quick and easy preparation of various menu items.

Almost any operation can benefit from the cost-savings and menu enhancements a Broaster pressure fryer has to offer.

To learn more about how pressure frying can increase your efficiency at the touch of a button, Contact us to get in touch with a sales representative and schedule a demonstration.

#BetterBeBroaster

About Broaster Frozen Foods - Boneless Buffalo Wings 🔥

Perfect grab ‘n go snack or great as an appetizer, our Boneless Buffalo Wings are made from tender, delicious 100% breast meat.

These tasty Boneless Buffalo Wings are marinated with a very mild heat & coated with our proprietary zesty breading. Your customers will love the lip-smacking flavor that these wings provide!

Our Boneless Buffalo Wings are carried at most Broadline Distributors and can be cooked in a Broaster pressure fryer or ventless fryer! 💯

#BetterBeBroaster #GenuineBroasterChicken

Dec 23

Today is the #FirstDayOfWinter!❄️

What better way to spend this winter day, than cozied up snacking on a juicy piece of Genuine Broaster Chicken while watching your favorite Christmas movie?

I don’t know, think about it.. 🤔😍

#BetterBeBroaster #GenuineBroasterChicken

Dec 21

#FAQFryDay: What foods are offered through Broaster’s Frozen Food Product Line?

The #ChickenExperts know!

👇

Broaster Foods offers you the finest quality marinated and breaded frozen chicken prepared by the same company that brought you world famous Genuine Broaster Chicken® more than 70 years ago.

You won’t find any formed or pressed chicken products in the Broaster Foods portfolio. Our products are all sourced from whole-muscle cuts and then marinated, breaded and par-fried, ready to go straight from your freezer to your fryer.

Broaster’s Frozen Food Line offers anything from Boneless Buffalo Wings and Premium Jumbo Popcorn Chicken, to Beer Battered Cod Filets and Seasoned Potato Wedges.

DM us for our full Frozen Food Line menu!

#BetterBeBroaster #GenuineBroasterChicken #RestaurantIndustry

Dec 20

One of our best selling items from our Frozen Food line are our Chicken Tenders! 💯

Broaster Chicken Tenders are made from tender, delicious, premium, 100% closely trimmed breast tenderloin. We never form, chop, extrude or process our chicken products, we cut these tenderloins directly from the breast & provide only the best! Our Chicken Tenders can be cooked in a Broaster pressure fryer or our ventless fryer.

🔺Marinated in our exclusive proprietary marinade

🔺Lightly breaded with our proprietary tenderloin breading for great consistency, moisture and flavor

🔺Quick cook time makes our Chicken Breast Tenders a great grab ‘n go item

Ask your local Broaster Distributor for availability!

#BetterBeBroaster #GenuineBroasterChicken

Dec 19

💥About our Ventless Countertop Fryer VF-3 With SmartTouch💥

Our Model VF-3 ventless fryer includes a round cooking well with 21lb cooking oil capacity. The unit is primarily stainless steel monocoque construction with a black, welded & powder-coated steel base plate. The interior cooking well tray is designed to capture spills up to 22.5 cups. The heating element is fully immersible with lift-and-lock mechanism for easy cleaning.

The SmartTouch Touch Screen Controller provides a programmable library with pre-loaded menu items & an automatic cook-cycle counter. The auto-comp feature automatically adjusts cooking time to accommodate for varying sizes and temperatures of load. On-screen prompts assist users in operation & maintenance functions.

Contact us for quote today! 😊

#BetterBeBroaster

Dec 18

Operator Spotlight!

If you’re looking for a place to eat, drink, bowl, or host a private event, @parktavernslp is your place! 🤩

Located in Saint Louis Park, MN, Park Tavern serves your favorite appetizers, burgers, pastas, tacos, Genuine Broaster Chicken wings, and pizza!

#BetterBeBroaster #GenuineBroasterChicken

Dec 17

#FAQFryDay: How do Broaster Trademark Food Programs Compare to Other Chicken Programs in the Market?

The #ChickenExperts know!

👇

At Broaster, we know one size does not fit all, so we build flexibility into our food programs. Our operators can customize their program as much or as little as they want. This gives our operators more control over the menu and its execution based on the kitchen, cooler, and food prep space available. It also allows operators to take the availablility and skill of their labor, and traffic into account.

All in all, compared to other quick-service food program providers like Krispy Krunchy, Chester`s, and Champs, Broaster offers a multitude of different options to help you serve fresh, great tasting food... on your own terms.

DM us for the full blog! 🔥

#BetterBeBroaster #GenuineBroasterChicken #RestaurantIndustry

Dec 13

💥About our E-Series 24G Pressure Fryer featuring Auto-Lift💥

The E-Series 24G cooks up to 64 pieces of fresh, bone in chicken per load thanks to shelving & racks.

Each shelf holds 2 full heads of chicken, or 16 pieces. Shelves can be preloaded to speed up prep time or breaded and loaded on demand.

Two inch high sides are perfect for large batches of Tenders. Request 1 inch or 2 inch high shelves on your order.

#BetterBeBroaster #GenuineBroasterChicken

Dec 11

Genuine Broaster Chicken is more tender, juicier, & flat out tastes better than ordinary fried chicken! 😍

#BetterBeBroaster #GenuineBroasterChicken

Dec 10

About Broaster Frozen Foods - Battered Cheddar Curds🧀

Our Battered Cheddar Curds are dipped in batter infused with craft beer straight from the keg and par-fried to crispy perfection.

Made from real Wisconsin yellow cheddar cheese that simply melts in your mouth, these curds are frozen & ready to cook!

Our Battered Cheddar Curds can be cooked in a Broaster pressure fryer or our ventless fryer. Ask your local Broaster Distributor for availability! 🤩

#BetterBeBroaster #GenuineBroasterChicken

Dec 9

#FAQFryDay: What Are The Benefits Of The E-Series 24G?

The #ChickenExperts know!

👇

Broaster’s E-Series 24G cooks the MOST amount of chicken in the LEAST amount of time, with the LEAST amount of energy using the LEAST amount of labor, oil, and hood space.

🔺Up to 35% gas energy savings,

🔺Up to 4X more days of useful oil life

🔺15-30 minutes of labor savings per day.

DM us for more info!

#BetterBeBroaster #GenuineBroasterChicken #RestaurantIndustry

Dec 6

Operator Spotlight!

This week’s operator spotlight goes to Copper Top Saloon in Kewaunee, WI!

Copper Top Saloon offers a variety of food options from pizza to burgers to Boneless Buffalo Wings from Broaster!

Check them out! 🔥

#BetterBeBroaster #GenuineBroasterChicken

Dec 5

We can stop eating Genuine Broaster Chicken whenever we want. Will we? …Probably not! 🤩

#BetterBeBroaster #GenuineBroasterChicken

Dec 4

Today is #GivingTuesday 🤲🏼

We believe that the best thing to give someone today is our delicious and juicy, Genuine Broaster Chicken.

It`s all about giving!

#BetterBeBroaster #GenuineBroasterChicken

Dec 3

The E-Series 24G cooks up to 64 pieces of fresh, bone in chicken per load thanks to shelving & racks.

High volume production has never been easier! 💯

#BetterBeBroaster #GenuineBroasterChicken

Dec 2